Custom Composite Materials

Discover how DeatexGroup’s technical nonwoven fabrics make it possible to create custom, sustainable, high-performance composite materials for every industry.

Custom Composite Materials: the Versatility of DeatexGroup Technical Fabrics

In a market increasingly focused on customization and high performance, DeatexGroup stands out as a leading technology partner in the development of custom composite materials, thanks to the versatility of its technical nonwoven fabrics.

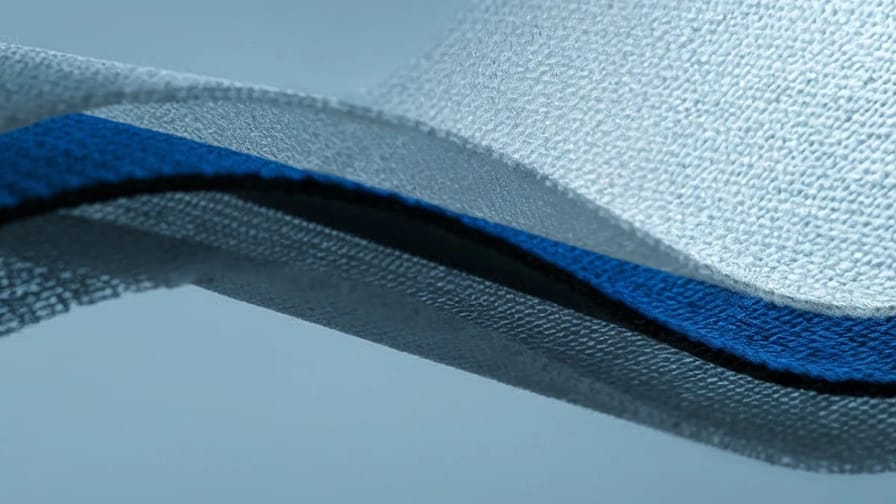

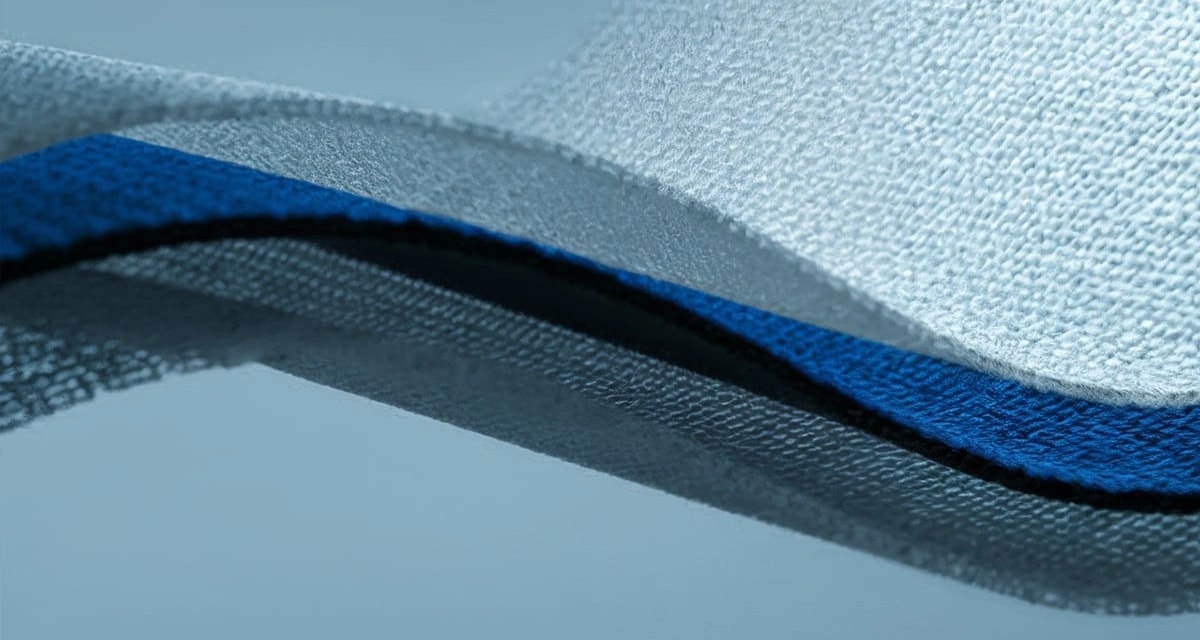

Our fabrics provide the ideal foundation for the creation of advanced solutions, achieved through lamination, co-extrusion, or bonding with plastic films, other fabrics, or functional substrates.

The result? High-performance composites that outperform their individual components, offering tangible benefits in sectors such as acoustic insulation, civil construction, and automotive, where technical fabrics act as separators and bonding agents between non-compatible materials.

Quality Control and High Performance

Thanks to highly controlled production processes, DeatexGroup ensures planarity, surface uniformity, and consistent quality—key elements for producing sophisticated laminates free from defects and with optimal adhesion.

Our Spunlace fabrics are available in weights ranging from 25 to 200 g/m², while other types of nonwovens cover a range from 60 to 1500 g/m², offering maximum design flexibility to adjust thickness, strength, breathability, elasticity, and aesthetics according to application needs.

Cross-Industry Applications

DeatexGroup technical fabrics have a wide range of applications, including:

- Technical apparel

- Furniture and interior design

- Automotive and transportation

- Construction and acoustic insulation

- Air filtration and treatment

- Industrial packaging

Each project is developed through direct collaboration with the client, with the goal of optimizing the performance of the final composite material.

Sustainability and Continuous Innovation

DeatexGroup is deeply committed to sustainability, offering biodegradable, compostable, recycled, and certified fabrics made with eco-friendly fibers.

These solutions help reduce environmental impact and promote a more circular, responsible supply chain.

Customization and Special Treatments

For branding or customization needs, DeatexGroup can print logos or trademarks directly onto the technical fabric.

Fabrics can be supplied as supports for subsequent lamination or developed in collaboration with the client to design the final composite.

Available options include:

- Thermo-adhesive coatings (with melt powder)

- Self-adhesive coatings (with quick-release film)

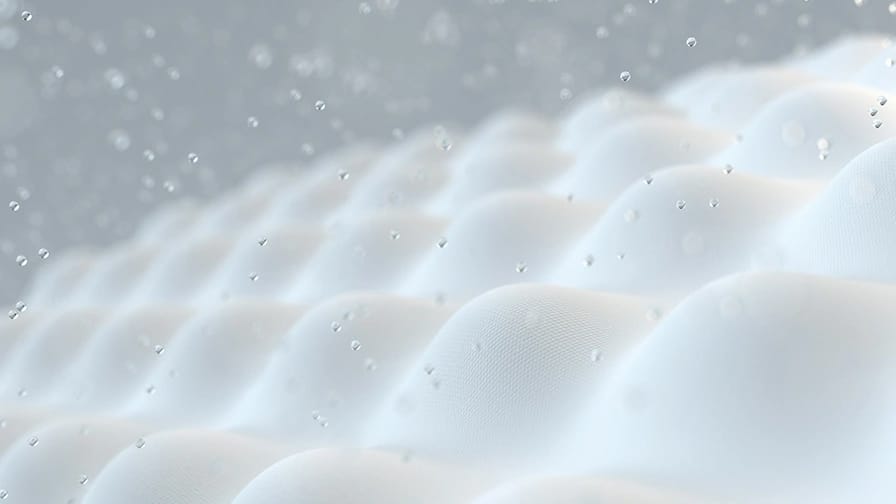

- Special treatments for water repellency, flame resistance, or other advanced technical properties

Through targeted impregnation processes, DeatexGroup ensures high performance and perfect integration into clients’ production workflows.

Develop Your Custom Composite Material

Would you like to develop a custom composite material for your industry?

Contact us today — the DeatexGroup team is ready to design the most suitable solution for your technical, aesthetic, and production requirements.

Let’s turn a technical fabric into your next competitive advantage.

Contact us for more information

Whether you are interested in our innovative products, would like more information on our sustainable processes or want to discuss a collaboration, the DeatexGroup team is ready to assist you.

Look for our FSC®, PEFC, GRS, OEKO-TEX® and Asthma Allergy Nordic certified products. Certification applies only to products bearing the respective logo. Certificates are available for download in the dedicated section.