DeatexGroup Technical nonwovens for Filtration: efficient and cost-effective solutions

Discover DeatexGroup technical nonwovens for air and liquid filtration: high-performance solutions for cleaner and more efficient working and living environments.

For over 40 years, DeatexGroup has been developing and manufacturing technical nonwovens for air and liquid filtration, serving a wide range of industrial sectors. The goal is to provide high-performance, energy-efficient solutions with an excellent cost-benefit balance.

Quality, efficiency and versatility

DeatexGroup technical nonwovens for filtration are designed to meet the most demanding requirements:

- Certified quality: every product comes with detailed technical data sheets

- Accurate lab testing: to support customers’ industry-specific certifications

- Energy efficiency: low air resistance and gradual fluid flow help reduce environmental impact and operating costs

- Customization: high flexibility based on application needs

- Purity and sustainability: mechanical bonding processes (like spunlace) with no chemical binders

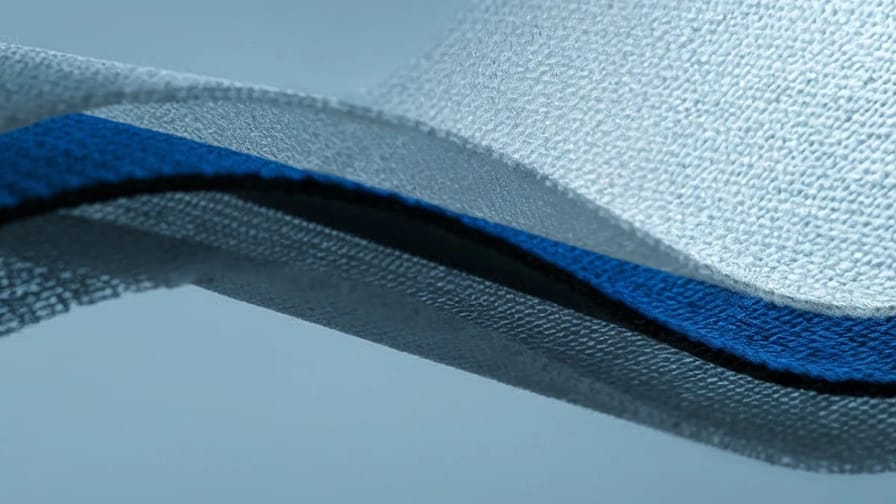

One of our solutions: Spunlace Technical Fabric

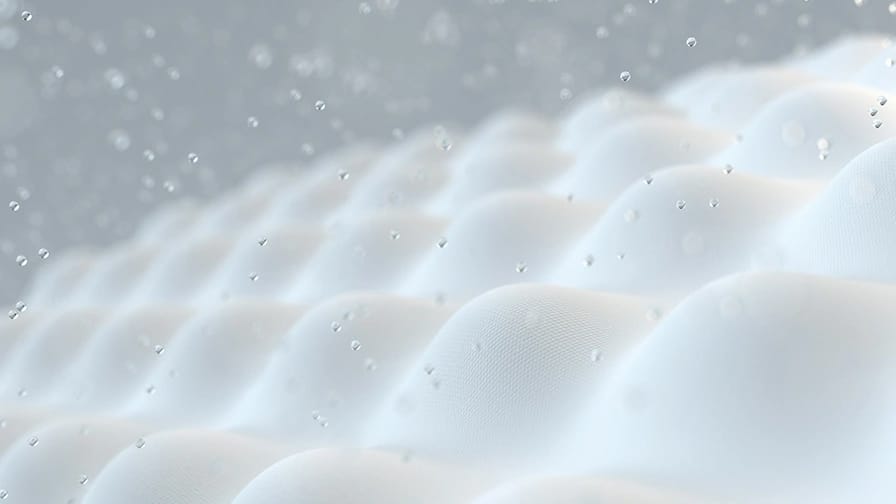

Spunlace (Hydroentangled Nonwoven) is one of the most versatile and eco-friendly filtration materials in the DeatexGroup range. It is produced through a high-efficiency process using high-pressure water jets to entangle fibers into a uniform structure, without chemical binders.

Fiber blends

A wide range of fiber blends can be created to customize the filter media, such as:

- Synthetic fibers (PES, PP)

- Artificial fibers (viscose, lyocell)

- Natural fibers (cotton, bamboo)

Available from 23 to 200 g/m², spunlace can be produced with parallel or cross-laid web formation and with various degrees of softness or stiffness depending on the final application.

Treatments and certifications

All DeatexGroup nonwovens can be treated to enhance specific properties:

- Hydrophobic or hydrophilic

- Oleophobic

- Flame retardant

- UV resistant

All certifications are available in our downloads page.

Performance and applications

DeatexGroup filtration nonwovens offer:

- High tensile strength and controlled permeability

- Optimized absorption and food compatibility

- Biodegradability, where applicable

Spunlace is capable of capturing microscopic particles and is used in:

- Industrial liquid filtration: coolants, water, oil, and process fluids (gravity, pressure or vacuum systems)

- Air filtration: spray booths, electronics, and protective masks

- HVAC filtration: prefilters and primary/secondary filters for ventilation and climate control systems

- Domestic water filtration: removing sediments and unwanted substances

- Filter media support: in automotive filters thanks to its strength and flexibility

- Medical applications: in certified healthcare devices

As the demand for cleaner indoor air grows, spunlace offers an optimal solution to control pollutants, allergens and harmful particles.

Compared to traditional materials, it ensures longer service life, fewer replacements, and lower maintenance costs.

Other filtration materials

Alongside spunlace, DeatexGroup also produces:

- Needle-punched nonwoven

- Waddings for air pre-filtration and filtration

Do you have a specific filtration challenge? Get in touch — our technical team will be happy to support you with the most suitable solution.

Contact us for more information

Whether you are interested in our innovative products, would like more information on our sustainable processes or want to discuss a collaboration, the DeatexGroup team is ready to assist you.

Look for our FSC®, PEFC, GRS, OEKO-TEX® and Asthma Allergy Nordic certified products. Certification applies only to products bearing the respective logo. Certificates are available for download in the dedicated section.